SIPs (Structural Insulated Panels) are a ‘green’ alternative to traditional framing.

Traditional framing uses dimensional lumber to build a frame, and then skins both sides with plywood or OSB (Oriented Strand Board) or a similar product. Insulation is added prior to the interior skin (batt), or blow-in after the interior skin is in place. On-site labor is a big cost component.

SIPs (Structural Insulated Panels) do this all in one step, in a controlled factory environment.

The build process consists of building a “sandwich” made up of OSB on both sides & an EPS foam interior layer. The designer or architect lays out the panels in consultation with an engineer familiar with SIPs construction.

What we learned was there are two ways to design SIPs panels; one of customized panels for efficient erection on site; the other for cost effective fabrication in the factory. The ideal of course would be to accomplish both with the same design; that’s where the designer needs to mesh with the engineer and the panel fabricator.

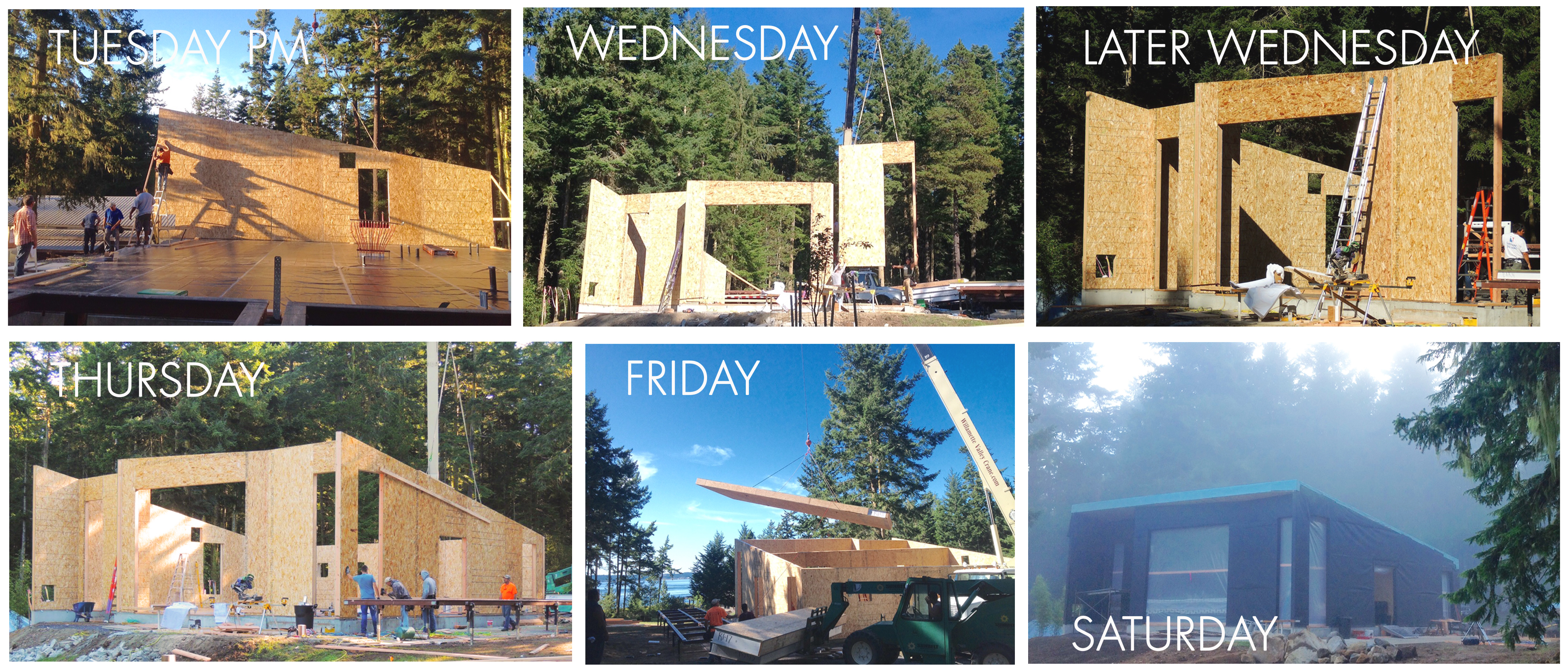

Could we have built the BARN GALLERY in FIVE DAYS with traditional framing?

Pretty unlikely, at 1600 square feet in size, on an island with limited resources, and doing it the traditional way…in this case the erection crew was in and out in less then one week. The windows and doors were delivered next, and installed in 2 days. That’s fully closed in after only 7 days!

The center interior wall consists of 6″ thick SIP panels, with openings for interior doors. The wall was designed and engineered to support the long roof panel spans above. The roof is 12″ thick with fabricated laminated splines incorporated into each panel as the structural component; each roof panel over 22′ long.

To facilitate the HRV, electrical and mechanical infrastructure, a “mechanical chase”, essentially an enclosed box, was designed into the plan ahead of time. It was built the full length of the center support wall and accommodates plumbing, electrical, audio/video cabling, and the Zehnder HRV comfo-tube pipes from Switzerland.

The interior bedroom and bathroom walls were built as traditional 2X6 “sound walls” with offset studs, to incorporate more complex electrical and plumbing such as the hanging toilets with reservoir tanks in the walls.

Would we recommend SIPs (Structural Insulated Panels)?

Given the speed of erection, the level of insulation (high R values, well above code requirements), we would absolutely choose this design/build process again. We definitely recommend that anyone building or doing extensive remodeling should investigate SIP construction when they are in planning mode! SIP construction is still not ‘mainstream’, so many designers and builders are not familiar with the methods yet. We think there is much to be gained with this sustainable building system.

©INCLINEDESIGN 2016